To download the data used in the lab use the following link: Index Site

1. Measurement Setup

Two-point measurement in Scanning Electron Microscope

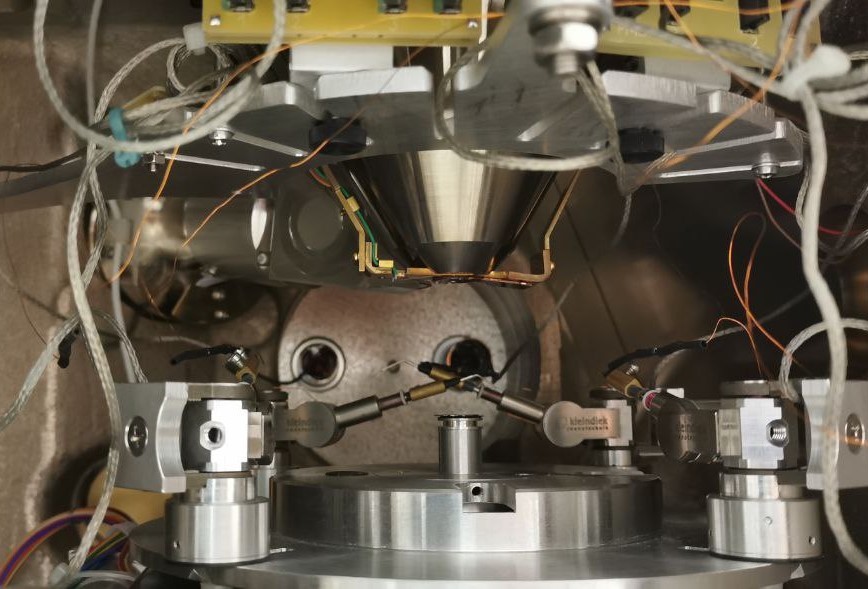

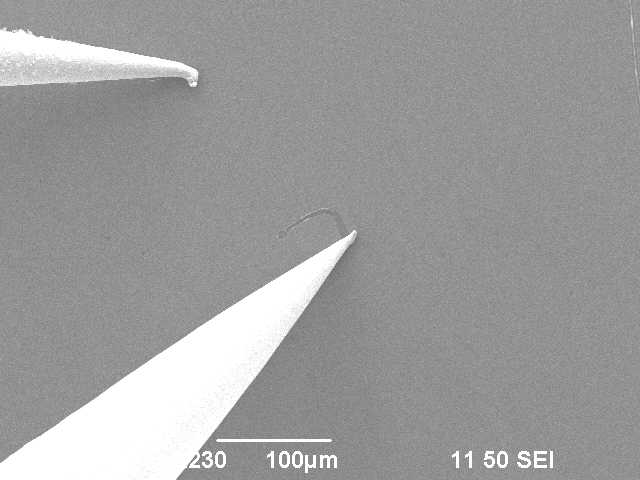

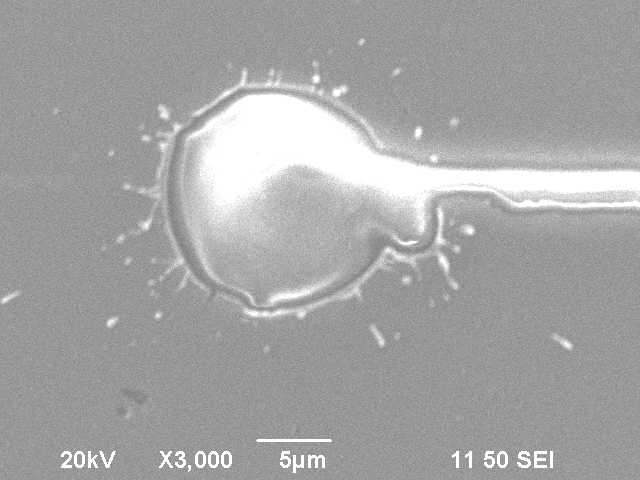

A two-point measurement was performed inside a Scanning Electron Microscope (SEM), see figure 1, to determine a characteristic current/voltage graph of a silver thin-film on a glass sample, the secondary electrons were measured inside the SEM. It is important to note that if the current gets too high the silver will melt under the manipulator arms inside the SEM resulting in possible loss of contact to the conducting silver thin-film and touching of the glass insulator. Moreover if the manipulator arms get too hot it is a possibility the manipulator arms start to move because of thermal expansion which results in a change of contact to the conducting film and therefore manipulating of the data. In addition during the experiment it was noticed that it is rather easy to scrath the silver thin-film on the glass sample even the nail of a finger could easily make a deep scratch. Furthermore, the layer thickness of the silver thin-film was measured using a profilometer, see figure 2.

Fig.1 Scanning Electron Microscope

Fig.1 Scanning Electron Microscope

Fig.2 Profilometer

Fig.2 Profilometer

2. Aims of the measurements

Two-point measurement in Scanning Electron Microscope

The purpose of the two-point measurement with the SEM was to get a feeling at which currents the silver started to melt or the manipulator arm of the SEM started to move because of thermal expansion. Moreover to find out at which current a hole was burned inside the silver thin-film, resulting in the manipulator arm of the SEM touching the glass insulator underneath the silver layer.

The following script was used to sweep the voltage silverfilm_SEM_current_ramp.py:

3. Results

Two-point measurement in Scanning Electron Microscope

It is noteworthy that in figure 3 two dips can be noticed in the thickness measurement of the silver thin-film sample at around $400\,\mu m$ and $1270\,\mu m$ inside the profilometer. This resulted from two scratches on the silver thin-film layer. The average thickness of the silver thin-film was measured to be about $36\,nm$.

Fig.3 Silver thin-film thickness measured with a profilometer over $2\,mm$ of sample

Fig.3 Silver thin-film thickness measured with a profilometer over $2\,mm$ of sample

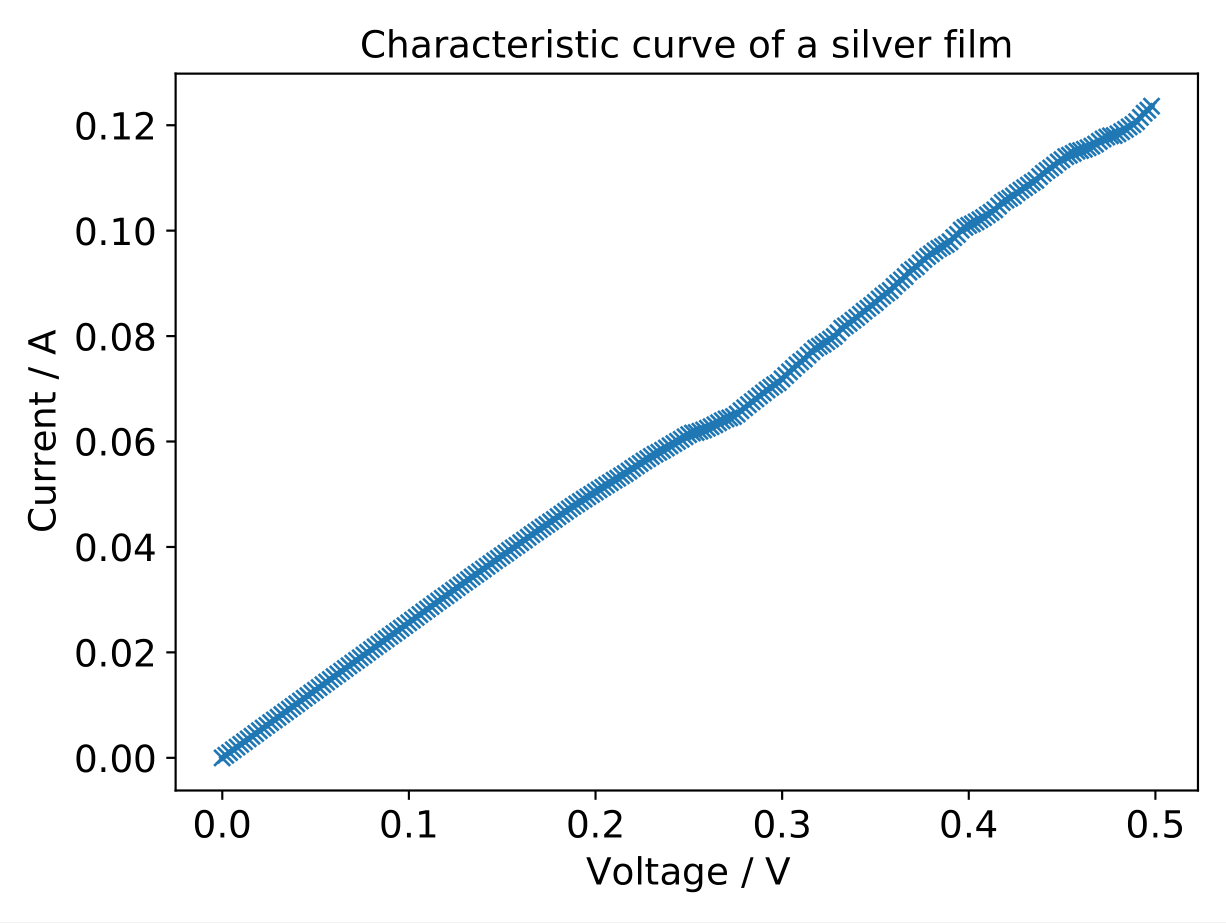

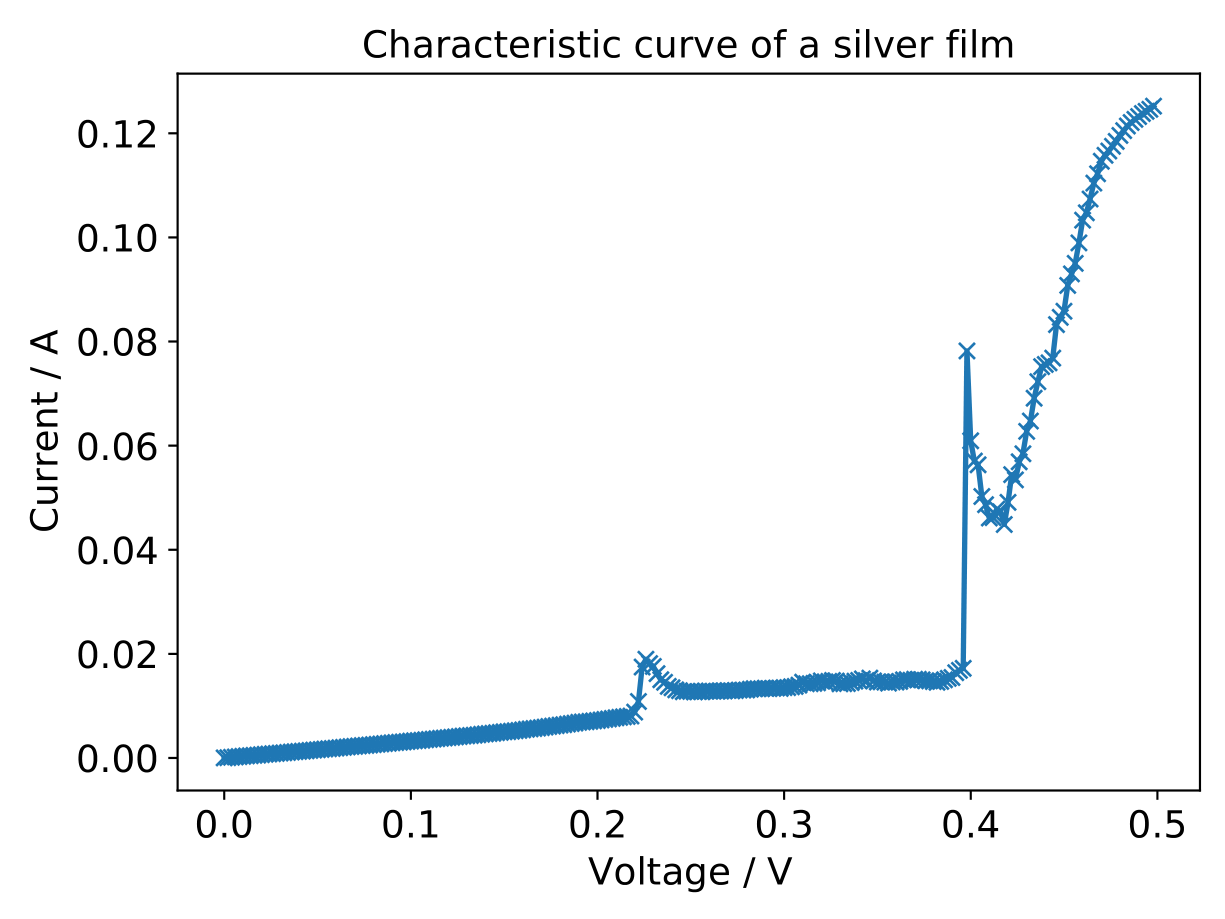

Fig.4 Current/Voltage curve of a silver thin-film in a SEM, from left to right:

IV measurement, Data;

IV measurement where the manipulating arm of the SEM moved because of thermal expansion, Data

Fig.4 Current/Voltage curve of a silver thin-film in a SEM, from left to right:

IV measurement, Data;

IV measurement where the manipulating arm of the SEM moved because of thermal expansion, Data

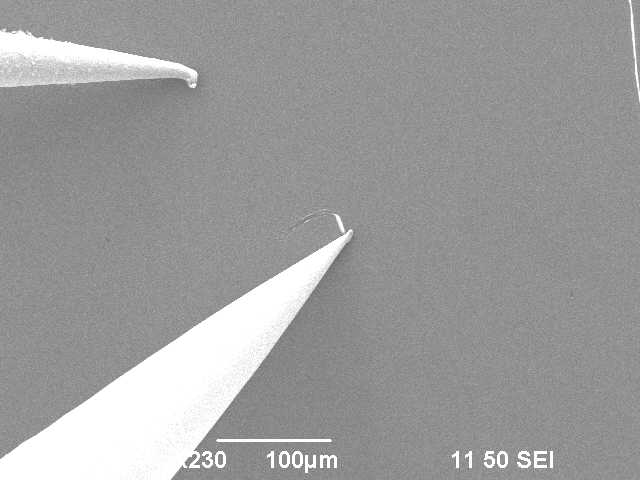

It is noteworthy that if the voltage gets high enough, electrons which gather in scratches (the glass underneath the silver is an insulator which leads to a collection of electrons) (figure 5 left, white color in scratch) are transported away by the manipulating arm of the SEM (figure 5 middle, black color in scratch). In figure 5 right melted silver is visible.

Fig.5 Two-point measurement inside SEM, from left to right: electrons in scratch; electrons are gone in scratch; melted silver

Fig.5 Two-point measurement inside SEM, from left to right: electrons in scratch; electrons are gone in scratch; melted silver

1. Measurement Setup

Four-point measurement in climate chamber

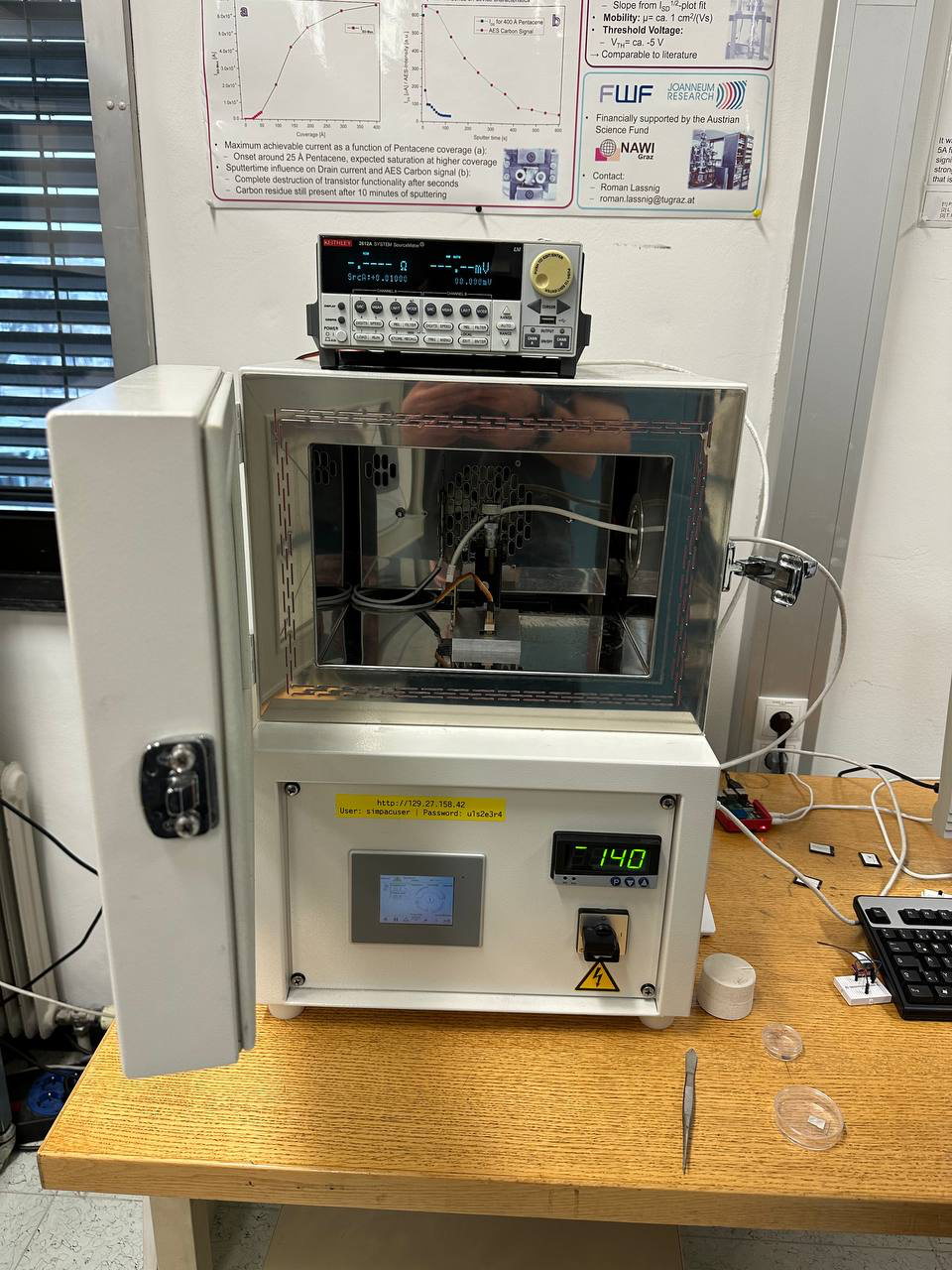

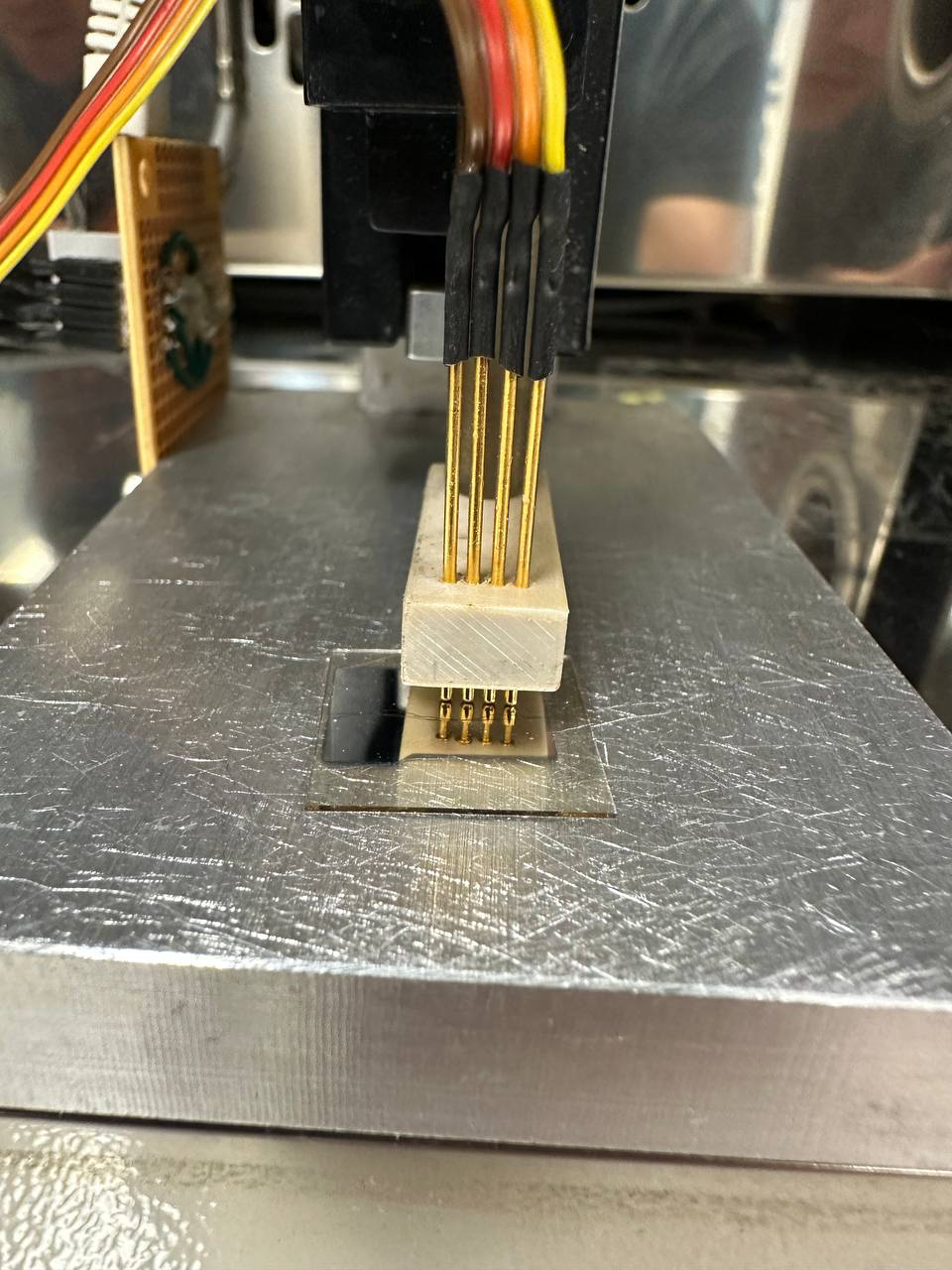

Four-point measurement is a method to determine the temperature dependence of the resistivity of a thin film. As can be seen in the measuring arrangement in figure 1, a current sweep is applied via the outer contacts. The electrical voltage is then measured across the middle contacts. It is important to ensure that the contacts are positioned as centrally as possible so that the electrical current lines can spread freely and falsification of the measurement can be avoided. Moreover if the current is set too high a hole can be burned into the silver film which then means the contacts are in touch with the glass underneath the silver thin-film which is an insulator. For the temperature dependence the four-point measurement device was placed inside the Vötsch VT4002 climate chamber (see figure 6) executing a temperature sweep from $10°C$ to $40°C$. A current sweep ran at every integer temperature. See figure 7 for the four-point measurment device with the silver thin-film sample.

Fig.6 Vötsch VT4002 climate chamber closed and open with four-point measurement device inside and a sourcemeter

Fig.6 Vötsch VT4002 climate chamber closed and open with four-point measurement device inside and a sourcemeter

Fig.7 Four-point measurement device with a silver thin-film sample

Fig.7 Four-point measurement device with a silver thin-film sample

2. Aims of the measurements

Four-point measurement in climate chamber

The aim of the four-point measurement was to determine the temperature dependence of the resistivity of a silver thin-film on a glass sample. For this purpose, the measuring device was placed in the Vötsch VT4002 climate chamber and the voltage and resistance were measured with a current sweep between $10\,°C$ and $40\,°C$. For each integer temperature the current was swept between $3\,mA$ and $10\,mA$ with a voltage limit at $2\,V$.

The following script was used to sweep the current and temperature 4pt_temperaturesweep_silverfilm.py:

3. Results

Four-point measurement in climate chamber

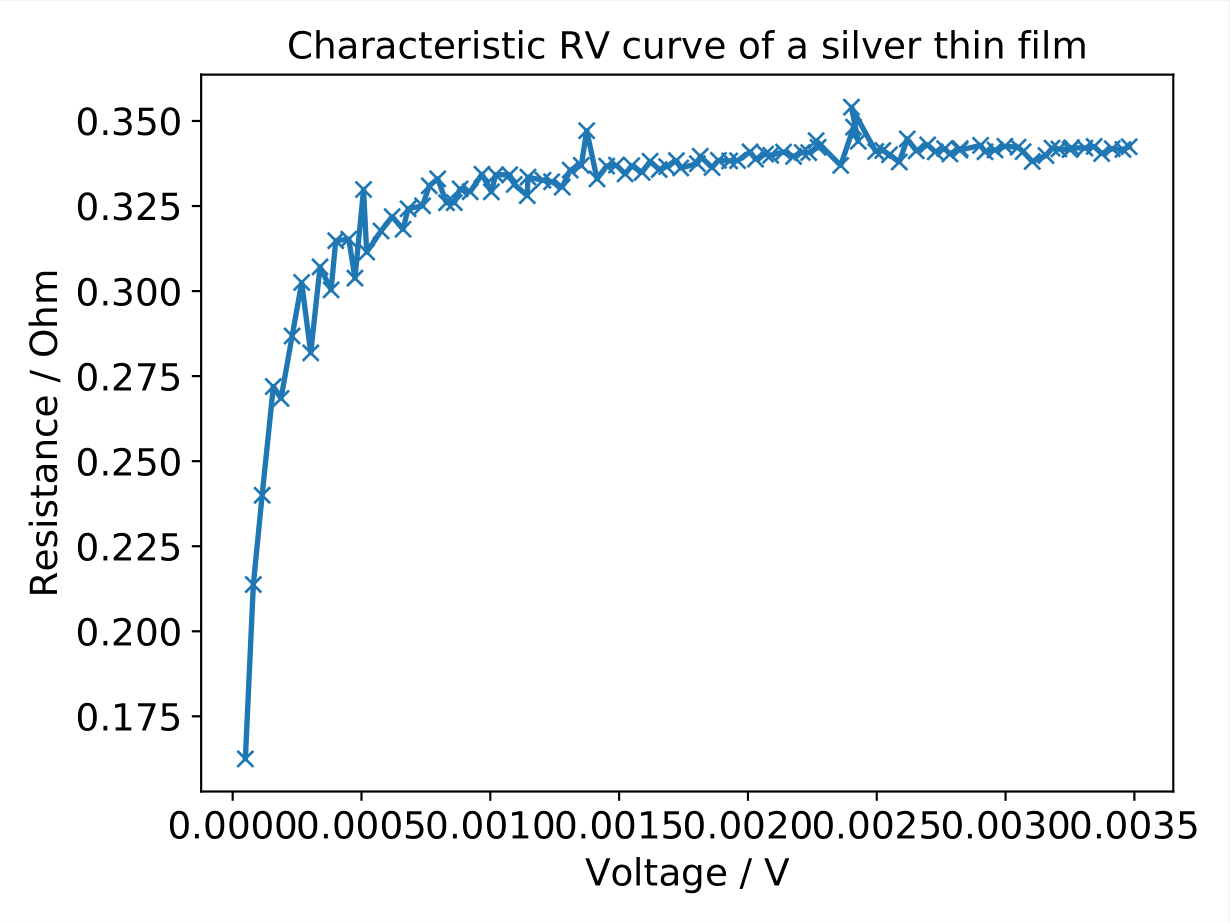

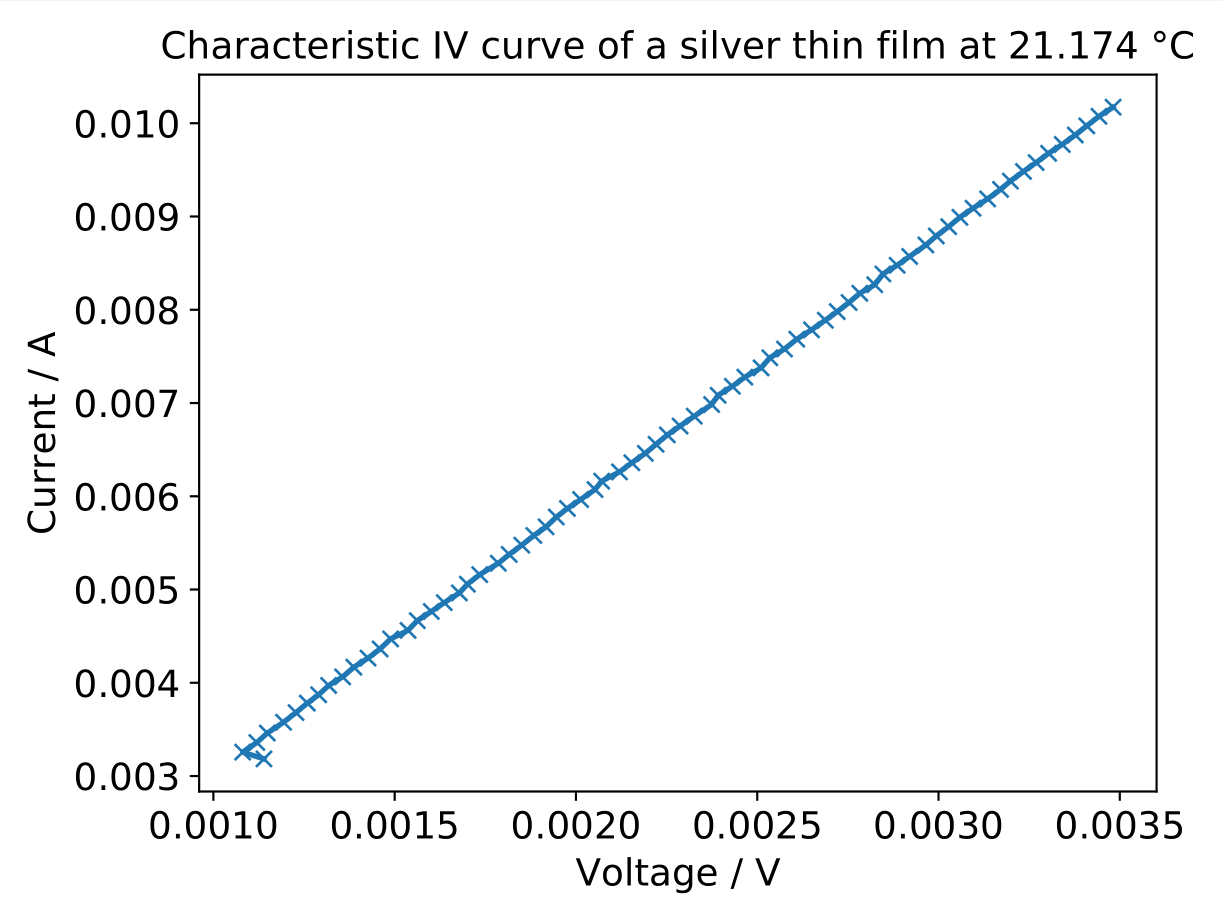

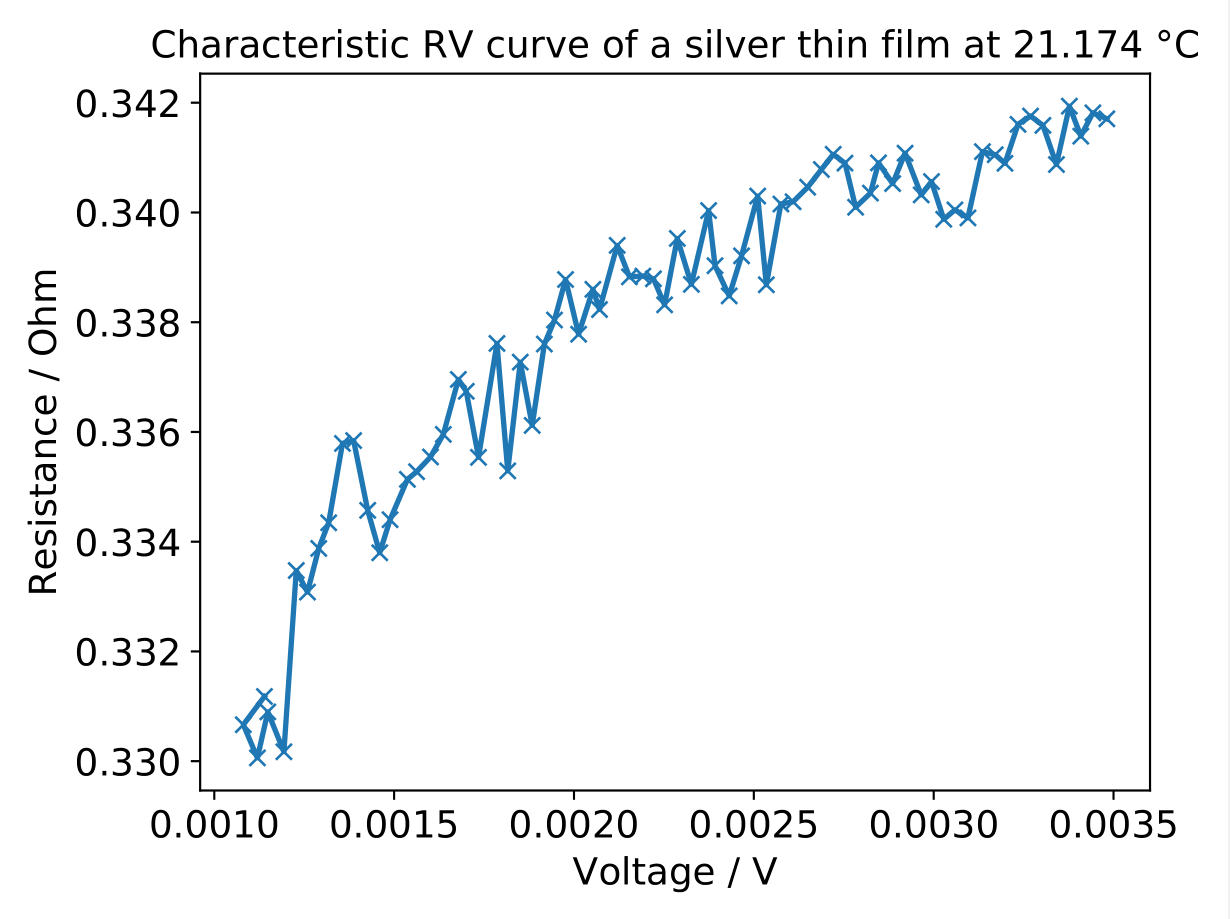

It is important to note that when the current gets too high during the four-point measurement the sample will heat up which ultimately defeates the purpose of the climate chamber. What can be learned from the SEM measurement is that it is really easy to scratch through the silver film with a finger or in general to destroy the silver thin film, e.g. if the current gets to high a hole is burned inside the film which leads to loss of contact during the four-point measurement. For this reason a range has to be found in which, the resistance does not change to much because of heating, the current does not get too high to essentailly damage the silver thin-film and in addition a not too low current where the sensitivity of the sourcemeter is too low. In figure 8 there is an example what happens to the resistance when there is no lower limit for the current, the resistance changes of about a facter 3 between $0\,V$ and $1\,mV$. The best range seemed to be from $3\,mA$ to $10\,mA$ while limiting the voltage to $2\,V$. Between this currents the resistance only changed in the hundreths of $\Omega$. The measurement at room temperature can be seen in figure 9 where a lower current limit was implemented.

Fig.8 Resistance/Voltage curve of a silver thin-film at room temperature with no lower current limit, Data

Fig.8 Resistance/Voltage curve of a silver thin-film at room temperature with no lower current limit, Data

Fig.9 Current/Voltage and Resistance/Voltage curve of a silver thin-film at room temperature, Data

Fig.9 Current/Voltage and Resistance/Voltage curve of a silver thin-film at room temperature, Data

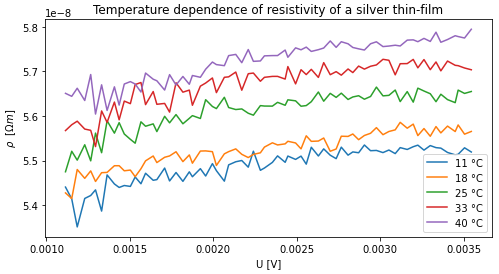

Using this parameters a temperature sweep from $10\,°C$ to $40\,°C$ was performed, ultimately giving a temperature dependend resistivity which can be seen in figure 10. Because the four contacts of the four-point measurement are in a straight line and equally spaced the formula for the sheet resistance takes a simple form. If the current is driven between the inner contacts and the voltage is measured between the outer countacts (or the current is driven between the outer contacts and the voltage is measured between the inner contacts), the sheet resistance is, $$R_{\text{square}}=\frac{\pi V}{\ln (2) I}\,\,\Omega /\square.$$

with

$$ \rho = R_{\text{square}} t$$ with $t$ being the thickness of the silver thin-film. The typical resistivity for silver is around $(1.5e-8)\,\Omega m$. The measured resistivity of the silver thin-film is about a factor 3 larger which is reasonable as a silver thin-film with unknown purity was used. It is noteable that the silver grain size of a silver thin-film is only as large as the thickness of the silver thin-film which was about $36\,nm$. This means a rise in resistivity in the polycrystal silver thin-film in comparision to a pure single silver crystal is expected as multiple grain borders lower the conductivity. It is noteworthy that the resistivity rises with temperature which is a typical behavior of metals. Fig.10 Resistivity at different temperatures of a silver thin-film plotted with the voltage,

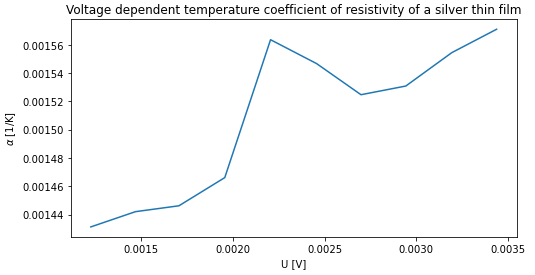

Fig.10 Resistivity at different temperatures of a silver thin-film plotted with the voltage,  Fig.11 Temperature coefficient of the resistivity at different voltages of a silver thin-film,

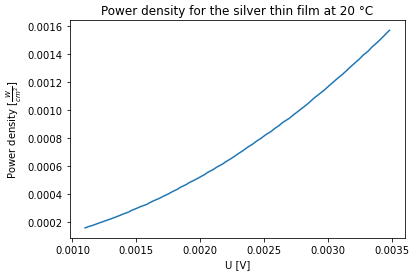

Fig.11 Temperature coefficient of the resistivity at different voltages of a silver thin-film,  Fig.12 Power density of a silver thin-film

Fig.12 Power density of a silver thin-film